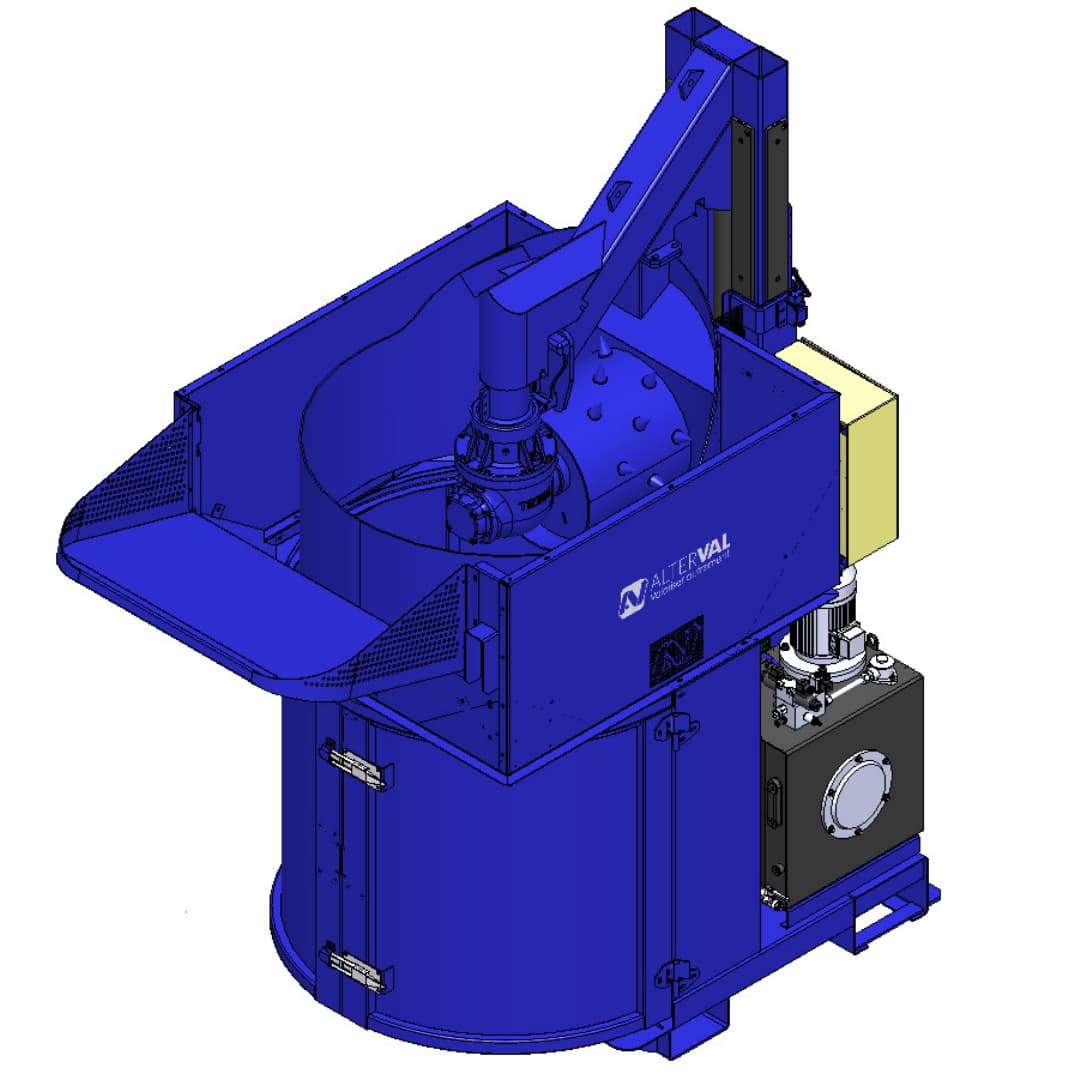

Valpak® – standard

1/ How does a VALPAK ® bag Rotary Compactor work?

The principle of the rotary compactor is that it reduces the volume of waste by means of its rotating head. The compacted waste is then recovered in 100% recyclable plastic bags, forming bales weighing between 250kg and 400kg.

It optimises the transport costs associated with waste management. In terms of its use, it offers the possibility of easy continuous loading and reduces to a minimum all handling between the place of waste production and storage.

2/ How do you choose a VALPAK® bag Rotary Compactor?

Alterval designs, manufactures, distributes and maintains the VALPAK ® bag Rotary Compactor in order to optimise the management of cardboard, plastic, wood, and other waste for companies. A compactor is chosen according to the nature and quantity of the waste, and the type of activity of the company. Alterval adapts to your needs and offers numerous solutions. Though there are other types of compactors such as the “Monobloc”, the “Fixed Station” or the Baler, the operating principle of a compactor remains similar.

3/ What are the advantages of our VALPAK® bag rotary compactor?

- The Valpak ® Rotary Compactor can be integrated directly into the production site.

- Practical: Easy to install the covers that collect the compacted waste. The rotary compactor does not require any prior handling: The

- Valpak ® receives cardboard, plastic or shaped crates.

- Ergonomics: No more repetitive movements and musculoskeletal disorders (loading at man's height). Simply throw the waste into the VALPAK compactor. Its photoelectric cell automatically triggers the compacting of the waste. Blockages are managed without any intervention (patented system).

- Continuous loading: An flashing light signals when the bale is full.

- Clean and convenient storage: The waste is

compacted in bags.

4/ Which sectors use our VALPAK® rotary compactors ?

- Industry

- Logistics

- Retail

- Production